Products

GYHCSD HR3 Servo Drive

HR3-CR2R8S2

The HR3 series stands as a cost-effective AC servo drive engineered for high-precision industrial automation. Delivering sub-micron level position control accuracy, it significantly elevates the precision, speed, operational efficiency, and long-term stability of automation equipment—empowering manufacturers to achieve higher productivity and consistent output quality.

Ideal for precision-critical sectors, this servo drive is widely trusted in laser processing, precision printing, and semiconductor manufacturing—where reliable, high-performance motion control is essential for mission-critical workflows.

product details

Core Features

• Input Voltage AC220v

• Rated current: 2.8A

• Supports 17bit~23bit single-turn/multi-turn absolute encoders

• Automatic loop parameter adjustment

• Enhanced vibration suppression function

• Speed control range: 0~12000 rpm

• Operating temperature: -40°C to +85°C

• Supports CAN Open, RS485, EtherCAT communication

• Multiple control modes: position/speed/torque control

Key Features

Items | Specification | ||

Basic Specification | Model | HR3-CR2R8S2 | |

Rated Current | 2.8A | ||

Input Voltage | AC220v | ||

Size | 252*270*84mm | ||

Control | IGBT SVPWM Control,Sinusoidal Current Drive Method | ||

Operation Conditions | Operation/Storage Temperature | 0℃~+40℃/-20℃~+70℃ | |

Humidity | <90%RH [No frost] | ||

Vibration/Shock resistance | ≤4.9G/19.6G | ||

Protection Grade | IP20 | ||

Pollution level | PD2 | ||

Operation Altitude | ≤5000m,1% capacity reduction for every 100m above 1000m | ||

Position control | Performance | Feedforward Compensation | Support speed feedforward (0~100.0%) setting to eliminate following deviation |

Command shaping | Low-pass filtering, mean filtering for Position command | ||

Frequency dividing output | Output | Phase A, B, Z: Differential outputs | |

Frequency division range | one rotate can divide any pulse in the range of 140 to 1048576 | ||

Speed/Torque Control | Performance | Current Loop Dynamic Characteristics | Step Response: 187.5µs (0~100%) |

Speed Control Range | 0~12000rpm, over 6000rpm,please contact with technical support | ||

Speed Loop Dynamic Characteristics | Step Response: 562.5µs(0~1000rpm) | ||

Torque Control Accuracy | ±2% | ||

Signal | DI (Digital Input) | Configurable:forward overtravel switch, reverse overtravel switch, home position switch, etc. | |

DO (Digital Output) | Configurable:Servo Ready, Speed Zero, Speed Reached, Position Reached, Position Approaching, Torgue Limit Active, Warning, Servo Error, etc. | ||

Features | Electronic Gear | Built-in two sets of electronic gear ratios, support gear ratio switching function | |

Limit Protection | The forward overtravel limit switch and reverse overtravel limit switch will immediately stop the system when activated. | ||

Protection Functions | Overcurrent, Overvoltage, Undervoltage, Overload, Stall, Main Circuit Detection Abnormal, Heat Sink Overheating, Overspeed, Encoder Abnormal, Parameter Abnormal, etc. | ||

Display | 5-digit LED Display, POWER LED CHARGE | ||

Wave suppression | The system is equipped with four notch filters, ranging from 50Hz to 5000Hz, all of which can be adaptively configured. | ||

Ease of Use | Self-tuning, speed observer, model following | ||

Debugging Interface | USB | ||

Others | Status display, alarm logging, JOG operation, etc. | ||

Interface Information Table

Type | Interface ID | Cores Qty. | Interface Definition | Remarks |

Power Supply | 9 | Motor Power out/AC power in | L1/L2/P/B/N/U/V/W/PE | |

I/O interface | CN1 | 44 | I/O interface | |

Encoder Interface | CN2 | 6 | Encoder Interface | 5v/GND/SD+/SD- |

RS485/CANOPEN in | CN3 | 8 | RS485+CAN In | RJ45 |

RS485/CANOPEN out | CN4 | 8 | RS485+CAN Out | RJ45 |

Debugging | MINI USB | 5 | MINI USB interface | VBUS/D-/D+/GND |

Previous article:JGDSD Series Servo Drive

Next article:JGDSD Series Servo Drive

Related products

-

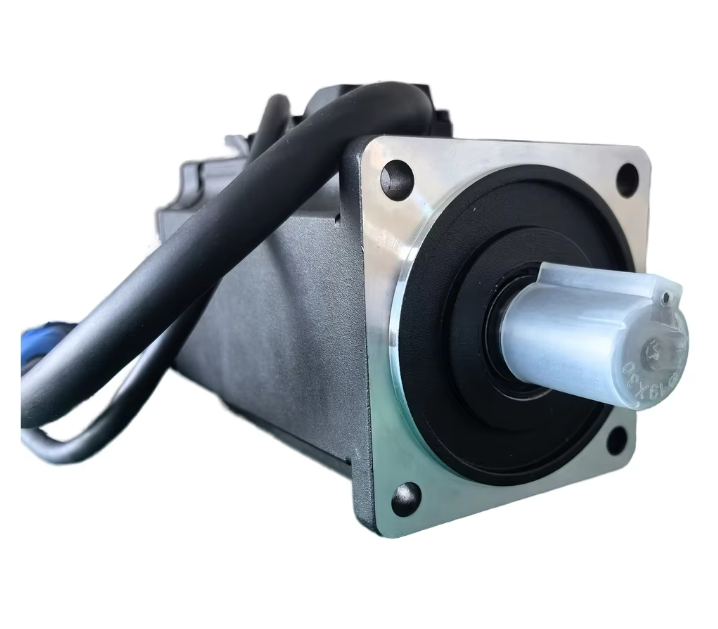

PRODUCT MODEL: GYHCSM M2 Servo Motor

-

PRODUCT MODEL: GYHCSM M2 Servo Motor

-

PRODUCT MODEL: JGSM Series Servo Motor

-

PRODUCT MODEL: JGSM Series Servo Motor